AUTOMOBILE PLANT WITH SMALL CARBON FOOTPRINT

US20250129628

2025-04-24

Fixed constructions

E04H5/02

Inventors:

Applicant:

Drawings (3 of 3)

Smart overview of the Invention

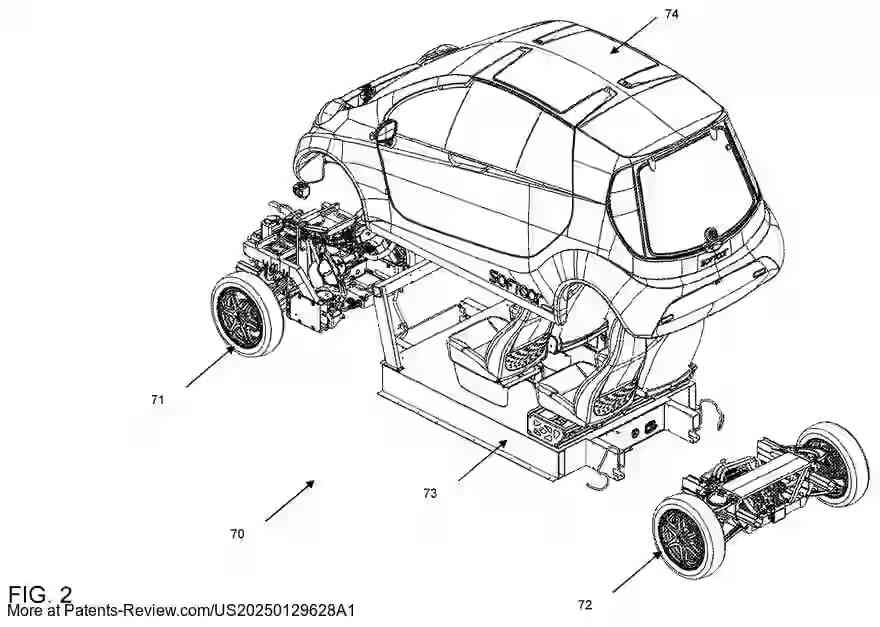

The patent outlines an innovative design for an automobile manufacturing plant focused on producing electric or hybrid vehicles with a minimal carbon footprint. The facility is distinct in that it eliminates the traditional metal processing line, which is a major source of pollution, noise, and vibrations. This allows the plant to be situated near residential areas, reducing the need for transporting vehicles over long distances and thus lowering additional energy consumption.

Technical Features

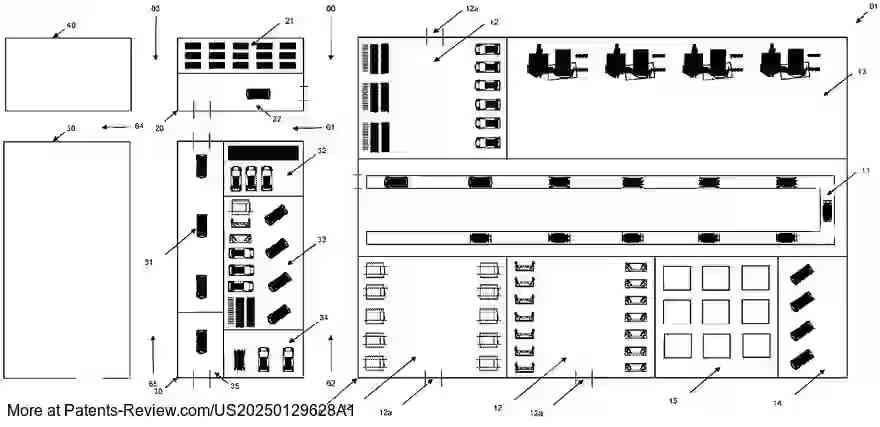

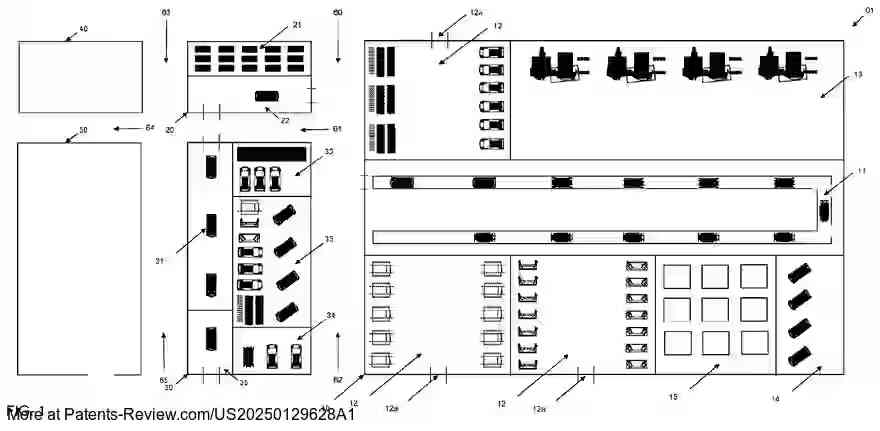

The plant's layout is designed to receive pre-assembled or partially assembled subassemblies, which are then put together without the need for steel transformation processes. This approach significantly reduces toxic emissions, chemical waste, and water usage. The plant includes various buildings, with high-risk operations like battery assembly being isolated to enhance safety. The modular nature of the assembly process allows for flexibility and efficiency in vehicle production.

Environmental Considerations

The absence of metal processing lines means the plant can achieve "zero" emissions and "zero" water pollution, crucial for its proximity to urban areas. It promotes sustainability by reducing grey energy consumption and facilitating recycling and retrofitting of vehicles. The design supports an SKD (semi knocked down) approach, where components are delivered by train to further minimize environmental impact.

Safety Measures

To address safety concerns related to battery fires, the plant includes a dedicated battery building isolated by fire breaks. This building is designed to be easily reconstructed if damaged. In case of a fire incident, operations can be shifted to a temporary battery tent also separated by fire breaks. This setup ensures that any potential hazards do not compromise the entire facility.

Additional Facilities

The plant incorporates various spaces such as showrooms for vehicle sales, retrofit areas for upgrading older vehicles, recycling zones for end-of-life components, and after-sales service (ASS) spaces for repairs and modifications. These facilities enhance customer engagement and support sustainable practices by encouraging vehicle longevity and material recovery.